While making PCB's at home isn't particularly difficult, If you've done any kind of building at all, you can appreciate how much difference it makes to stuff a pre-printed PCB versus hand wiring on bread board or GPB.

All you Need is:

First of all software I use to design the PCBs is Protel DXP, or you can use EAGLE PCB. Protel DXP is not Free ware, you have to purchase the licence to use that.

EAGLE is free, put out by CadSoft.You can download for free either for a Linux or Windows version of this layout tool, whose only limitation is a maximum of one schematic page and about a 2.5x4" PCB size.

All you Need is:

- PCB Designing Software

- Simple Copper Plated PCB Cost: RS 100 Max

- Nearest Computerized Car Number Plate Maker..!! Cost: Can be any 50-500 RS.

- Etching Solution Cost: Rs.90 per 500GMS

- Water

- Container

- Small Hand Drill Cost Rs.150

First of all software I use to design the PCBs is Protel DXP, or you can use EAGLE PCB. Protel DXP is not Free ware, you have to purchase the licence to use that.

EAGLE is free, put out by CadSoft.You can download for free either for a Linux or Windows version of this layout tool, whose only limitation is a maximum of one schematic page and about a 2.5x4" PCB size.

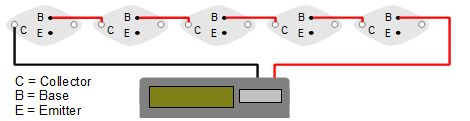

For the demostration I'm going to show you simple bridge circuit, with Protel DXP.

Now,

Make the Schematic file in the Protel DXP but putting components in the schematic capture,connect each components and after adding PCB to the project, I will import that whole schematic in to the PCB.

Now the PCB Viewer is opened, and arrange the components and route the whole PCB using Auto routing.

Now what to have to do is,Go to File> Print out the PCB file using the virtual PDF installed on you machine and save it to the .PDF flie.

STEPS TO MAKE IT HARD:

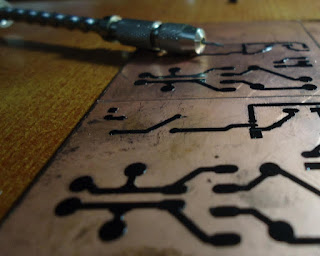

- After printing this file to the .PDF format, convert that file to .JPEG using Adobe Photoshop(PS) also do it "X - Mirror" in PS. Save it as .JPEG. Take this .JPEG file and the perfect size of your PCB file in mm (That can be done be CTRL+M in Protel DXP) to the nearest Computerized Car Number Plate maker.

Making it X-Mirror is very important as you have whole track in the bottom layer. - Give this JPEG file and let him cut through his computerized Plotter on a thick sticker and stick that sticker to your copper plated PCB.

- See how my circuit looks like.(I have used another circuit down here, but yours will be nearly same)

- Etching Safety Precautions :

- Wear Hand glows while putting/taking out circuit in/from solution, as the solution heats up too much when you add FeCl3 in to water, and also can harm your skin.

- The solution you have to use is FeCl3(two table spoons for small size PCB) + some hot water(not too much!!), which is used in the laboratories. It will not be a nightmare if you disliked the Chemistry..!! (sorry have taken another different image, picture is just to demonstrate you the process of making PCB, FYI : it's from my LAB only, not copied from the internet.!!).Put it in this solution for whole day in one container.

After putting it in the Etching Container for whole day, take it out, wash your circuit and peel off that sticker.

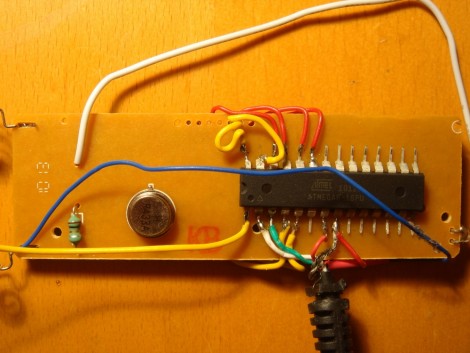

This is the image after the whole process.

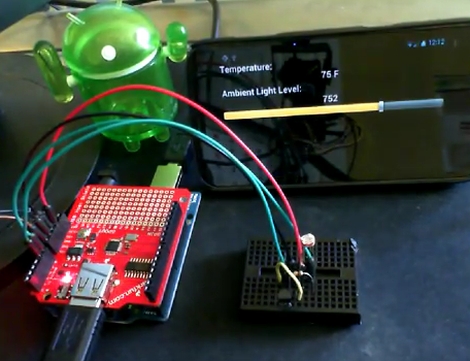

Drill the holes at your desired places. Mount the components.

Enjoy Electronics...!!!

The coordinates, computed from the measurements, should refer to the main axis very precisely and reliably. However, anomalies arise from movement due to wind, cranes, sun radiation and other loads, and vibrations within the tower (Figure 1). Conventional methods for monitoring tall towers, such as optical plumbing, are incapable of compensating for such anomalies, and this is an intolerable drawback when the towers are super high-rise, such as the Burj Khalifa in Dubai. To control such towers, Leica Geosystems developed and proof-tested a new measurement system based on GNSS (GPS and Glonass) combined with high-precision inclination sensors and total-stations. The surveying procedure, called Core Wall Control Survey System (CWCSS), has been applied to the Burj Khalifa in Dubai, UAE; the Al Hamra tower in Kuwait; the Landmark tower in Abu Dhabi; and other high-rise buildings around the world, and has been patented under International Publication Number WO 2007/080092 A1.

The coordinates, computed from the measurements, should refer to the main axis very precisely and reliably. However, anomalies arise from movement due to wind, cranes, sun radiation and other loads, and vibrations within the tower (Figure 1). Conventional methods for monitoring tall towers, such as optical plumbing, are incapable of compensating for such anomalies, and this is an intolerable drawback when the towers are super high-rise, such as the Burj Khalifa in Dubai. To control such towers, Leica Geosystems developed and proof-tested a new measurement system based on GNSS (GPS and Glonass) combined with high-precision inclination sensors and total-stations. The surveying procedure, called Core Wall Control Survey System (CWCSS), has been applied to the Burj Khalifa in Dubai, UAE; the Al Hamra tower in Kuwait; the Landmark tower in Abu Dhabi; and other high-rise buildings around the world, and has been patented under International Publication Number WO 2007/080092 A1. Core walls are constructed bit by bit, one on top of the other. Each core wall element consists of several concrete pours. The placement of the formwork structure on top of existing core walls should be done very precisely, determined from the position of previously placed elements. For this purpose control points, materialised, for example, by nails, have to be set in the top of the concrete. The basic task of the surveyor is to determine the coordinates of these control points and to compute and stake out the position of the formwork structure in a design reference system based on the main axis of the tower. Basically, the work consists of measuring angles and distances with a high-grade total-station positioned on a ground control point (GCP). In the new CWCSS system the total-station remains the main instrument, providing as it does distances and angles to compute the coordinates of control points and any other mark or object in the structure. On most construction sites surveyors carry out their work in the midst of a tangle of steel and other obstructions, and beneath or beside materials lowered by cranes; working areas are congested with materials, equipment and men and, of course, working at height requires special safety measures. Under such conditions, GCPs on which the total-stations can be positioned are scarce. So the CWCSS system is based on positioning total-stations from measurements to three or four GNSS (GPS + Glonass) receivers to which 360° reflectors are attached beneath the antenna (Figure 2).

Core walls are constructed bit by bit, one on top of the other. Each core wall element consists of several concrete pours. The placement of the formwork structure on top of existing core walls should be done very precisely, determined from the position of previously placed elements. For this purpose control points, materialised, for example, by nails, have to be set in the top of the concrete. The basic task of the surveyor is to determine the coordinates of these control points and to compute and stake out the position of the formwork structure in a design reference system based on the main axis of the tower. Basically, the work consists of measuring angles and distances with a high-grade total-station positioned on a ground control point (GCP). In the new CWCSS system the total-station remains the main instrument, providing as it does distances and angles to compute the coordinates of control points and any other mark or object in the structure. On most construction sites surveyors carry out their work in the midst of a tangle of steel and other obstructions, and beneath or beside materials lowered by cranes; working areas are congested with materials, equipment and men and, of course, working at height requires special safety measures. Under such conditions, GCPs on which the total-stations can be positioned are scarce. So the CWCSS system is based on positioning total-stations from measurements to three or four GNSS (GPS + Glonass) receivers to which 360° reflectors are attached beneath the antenna (Figure 2).

To determine the offset caused by movements of the tower, dual-axis precision inclination sensors, which measure the exact offset from the vertical of the tower, are installed at ground level and about every given number level above. Mounted on the core wall along a vertical line, these measure any variation in tilt of the main axis of the tower. The offsets calculated from these measurements are used to correct the coordinates of the control points as measured by the total-station, ensuring that the building is constructed as straight element, pointing precisely vertically, regardless of movement. To calibrate the inclination sensors, tilt values can be compared with measurements gained through vertical laser plummet beams passing through holes made on different levels, the method used for the Burj Khalifa, or using a motorised high-precision dual-axis inclination sensor, as for the new Ryiad Tower in Saudi Arabia.

To determine the offset caused by movements of the tower, dual-axis precision inclination sensors, which measure the exact offset from the vertical of the tower, are installed at ground level and about every given number level above. Mounted on the core wall along a vertical line, these measure any variation in tilt of the main axis of the tower. The offsets calculated from these measurements are used to correct the coordinates of the control points as measured by the total-station, ensuring that the building is constructed as straight element, pointing precisely vertically, regardless of movement. To calibrate the inclination sensors, tilt values can be compared with measurements gained through vertical laser plummet beams passing through holes made on different levels, the method used for the Burj Khalifa, or using a motorised high-precision dual-axis inclination sensor, as for the new Ryiad Tower in Saudi Arabia.